-40%

Gecko GR214v Raptor Drive/Heatsink & Nema 23 600oz 3.5a Stepper

$ 150.47

- Description

- Size Guide

Description

Please review the entire listing, and all videos as they cover all the details of this professional automation package.This package features Gecko's most advanced stepper drive, custom machined tool less mounted heatsink, and Nema 23 600oz/in stepper motor.

This listing is for one drive, one heatsink, and one motor.

The drive's specs are below, along with the heatsinks, and motor's.

Cooler Running Temperature:

Upgraded, and over-rated power section components equal

30% reduction in heat compared to previous stepper drive revisions

.

Extra Resolution Choices: Ranging from half-step to 256-microstep resolution, a stepper can be run up to a resolution of 51,200 steps per revolution of your motors shaft.

This is 25.6 times the resolution capability of a G540 drive!!

Sub-Microstepping:

At certain microstep resolutions the GR214V will automatically interpolate microsteps between rougher resolution choices. This means that the motor will move with the smoothness of a higher resolution option but will still have the lower input frequency requirement of the selected resolution. When operating in 2uStep, 4uStep and 8uStep modes the drive will interpolate to 16uStep motor smoothness. When operating at 5uStep the GR214V will interpolate to 10uStep smoothness. Higher levels of interpolation have significantly diminished returns, which is why this affects only lower resolution choices.

Resonance Compensation:

Using an entirely new method of motor control allows the GR214V to eliminate nearly all resonance.

The two-tier system the drive uses eliminates resonance at the 1st and 2nd harmonic and at the midband, increasing torque and motor stability in unstable step motor regions.

Full Step Morphing:

Like all other Geckodrive stepper drives the GR214V has full step morphing. Between 3 – 6 RPS the drive will morph from microstepping to a true full step output to the motor,

increasing high speed motor torque by 40% over a microstepping only driver.

This requires no input from the user and the drive will not need any modifications in the software controlling it to take advantage of this.

Soft Start:

Step motors without a soft start drive operating them can draw significant inrush current. The GR214V ramps up current to the motor to avoid startup noise and premature tripping of protection circuitry due to sudden current loads.

Spread Spectrum PWM:

Most stepper controls have a fixed switching frequency which leads to motor harmonics and large EMI outputs.

With spread spectrum PWM the GR214V switches randomly between switching frequencies at every step, eliminating harmonic knocking and EMI interference.

Self-Test:

A push button is used on the GR214V to allow for quick in-the-field testing of the drive’s core functionality. With a motor and power supply connected correctly the motor will turn at 1 RPS clockwise and counter-clockwise as long as the button is held down. This button input will take priority over all other input signals, meaning if STEP and DIRECTION are connected and the button is held down the GR214V will move in self-test mode.

Protection Circuitry:

The GR214V has rugged protection features to prevent damage in the majority of catastrophic events.

It is protected against short-circuit, under-voltage, over-voltage, and over-temperature. The protection circuit will also detect an open motor phase and an unconnected motor

. To clear a FAULT state the RESET input must be cycled to logic ‘0’ for one second and then returned to a floating or logic ‘1’ state.

User adjustable standby current.

If the onboard DIP switch is used to set phase current the user can adjust a trimpot for holding torque from 0% - 100% current in standby mode. If an external resistor or voltage is used the user may use a second resistor to set standby current, allowing full customization on multi-axis applications.

After the GR214V has not received step pulses for one second it will enter standby mode, where it will limit current to a user-set percentage of

maximum current. The GR214V will enter reduced-heating switching mode during this time to further decrease motor temperature during times of inactivity

.

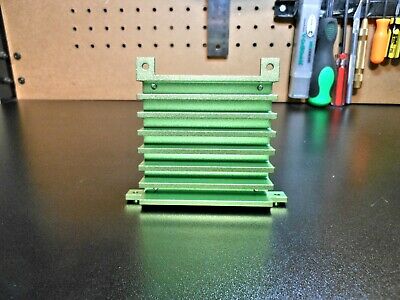

My custom machined 6061 aluminum anodized heatsink in this package come pre-mounted to the drive with thermal compound,

and allows the end user the options of mounting the drive vertically, or horizontally to fit virtually any electronics enclosure

. The heatsink also features tool less mounting with thumb nuts for ease of installation, and servicing

all included with this DIY kit

.

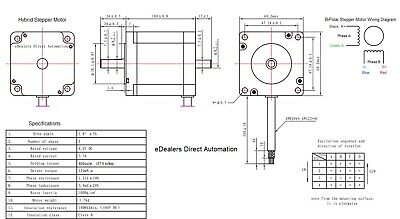

The other included component is one of my Nema 23 600oz 8mm dual shaft (

37.

5in/lbs

) stepper motors with 3.5a rating (3.9mh Inductance Rating).

If your looking for the largest torque Nema 23 motor available you've found it. I designed these to save the expense of upgrading to a Nema 34 motor for CNC systems with Nema 23 motor mounts.

The complete motor specs are below.

Please review the overview video below of me covering the features of these drives.

Gecko Raptor GR214V Drives (High Resolution Bullet Proof Drive) - YouTube

Video will open in a new window

Using the eBay App? Paste link into a browser window:

[isdntekvideo]

This drive, heatsink, motor package price includes USPS 2-3 day priority mail for the fastest most economical delivery for US orders.

Shipping in the US is FREE

All my international orders are handled through eBay's Global Shipping Program as they offer us both the best protection against loss, and damages. Please review their policy for a shipping quote based on your specific location as they don't disclose it to me.